- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Other

1.5 years, 12 Months

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops, Advertising Company

Video technical support, Online support, Spare parts, Field maintenance and repair service

None

None

New

Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, Apparel, Textiles, corrugated machine

Film, Case

Plastic, Wood

Automatic

Electric

220V/380V

6.5kw

Hebei, China

xinglong

depends

Machine Model

CE ISO

Long Service Life

Engineers available to service machinery overseas

you like

Automatic Carton Box Packing Machine

Making Carton

120pcs/min

Corrugated Cardboard printing Die Cutting

Sun feeder high speed rotary die-cutting machine packing machine

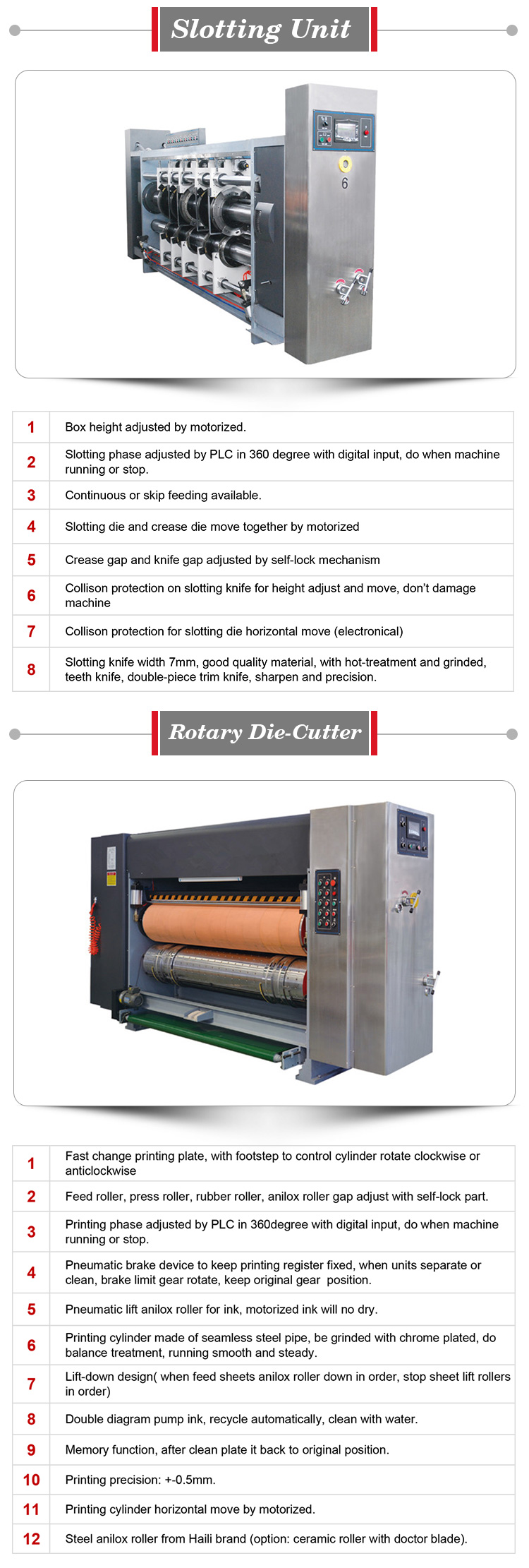

Main mechanisms performance

1. Adopt lead edge feeding system . Adjust wind volume according bending degree to ensure feeding paper smoothly 2. The rubber roller with air cylinder device ,feeding accurately , stably , not destroy paperboard strength if the feeding space is very small.

3. The left and right side baffles adopt electric control with data display(options: pneumatic lifting device ) the back baffle box adopt electric adjustment , the front baffle space by manual adjustment.

4. Equipped with colors touch screen take 360 degree set to die roller , display product speed and set production quantity .

5. The rubber roller adopt mechanical control the position move left and right .the movement distance is 40mm.

6. The space of rubber roller with die roller adopt automatic looking device .and with air cylinder can adjust quickly ,reduce rubber wear ,prolong use lift.

7. With speed compensation device make rubber roller rotate with die roller ,make the surface speed of the rubber cushion is completely controlled by dies .The shape of the carton will absolutely equal to the dies.

8. With rubber repair device ,the rubber can be used after repaired.

9. All of rollers are made of good quality steel .Surface be grinded ,tempering,hard chromed plate.

10. Drive roller used good quality alloy steel ,after heat treatment ,be grinded .Gear closed cycle spray lubrication ,automatic balance engine oil device ,keep every unit oil level is equal.

11. Main motor use frequency converter adjustment.

Technical parameters:

| Model | QYKMA2800 |

| Machine inside width (mm) | 2800 |

| Max feeding paper size(mm) | 1200*2600 |

| Max effective printing size(mm) | 1200*2400 |

| Min coverage size(mm) | 380*500mm |

| Min slotting space(mm) | 290*80*290*80 |

| Design speed(pcs/min) | 150pcs/min |

| Working speed(pcs/min) | 120pcs/min |

| Min coverage size(mm) | 6mm |

| Printing precision | ±0.75mm |

| Thickness of cardboard | 1.2-9mm |

| Wall thickness | 40mm |

| Main motor powe | About 15KW |

Sun feeder high speed rotary die-cutting machine packing machine

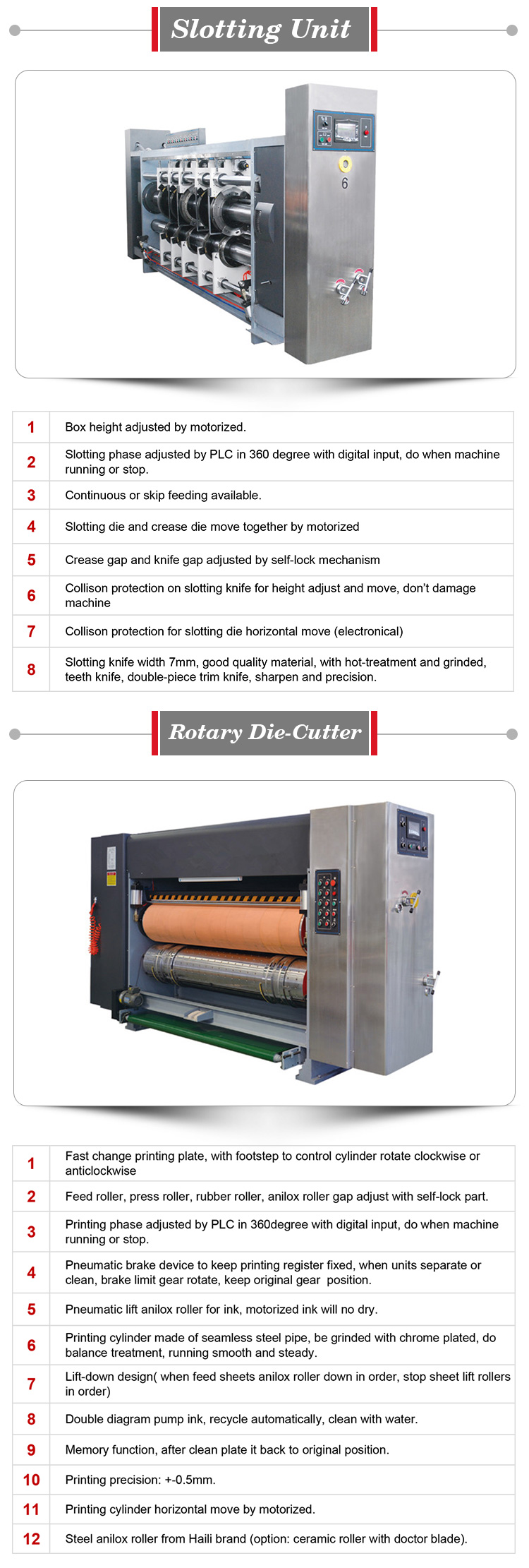

Main mechanisms performance

1. Adopt lead edge feeding system . Adjust wind volume according bending degree to ensure feeding paper smoothly 2. The rubber roller with air cylinder device ,feeding accurately , stably , not destroy paperboard strength if the feeding space is very small.

3. The left and right side baffles adopt electric control with data display(options: pneumatic lifting device ) the back baffle box adopt electric adjustment , the front baffle space by manual adjustment.

4. Equipped with colors touch screen take 360 degree set to die roller , display product speed and set production quantity .

5. The rubber roller adopt mechanical control the position move left and right .the movement distance is 40mm.

6. The space of rubber roller with die roller adopt automatic looking device .and with air cylinder can adjust quickly ,reduce rubber wear ,prolong use lift.

7. With speed compensation device make rubber roller rotate with die roller ,make the surface speed of the rubber cushion is completely controlled by dies .The shape of the carton will absolutely equal to the dies.

8. With rubber repair device ,the rubber can be used after repaired.

9. All of rollers are made of good quality steel .Surface be grinded ,tempering,hard chromed plate.

10. Drive roller used good quality alloy steel ,after heat treatment ,be grinded .Gear closed cycle spray lubrication ,automatic balance engine oil device ,keep every unit oil level is equal.

11. Main motor use frequency converter adjustment.

Technical parameters:

| Model | QYKMA2800 |

| Machine inside width (mm) | 2800 |

| Max feeding paper size(mm) | 1200*2600 |

| Max effective printing size(mm) | 1200*2400 |

| Min coverage size(mm) | 380*500mm |

| Min slotting space(mm) | 290*80*290*80 |

| Design speed(pcs/min) | 150pcs/min |

| Working speed(pcs/min) | 120pcs/min |

| Min coverage size(mm) | 6mm |

| Printing precision | ±0.75mm |

| Thickness of cardboard | 1.2-9mm |

| Wall thickness | 40mm |

| Main motor powe | About 15KW |

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169