- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Other

1.5 years, 1 Year

Manufacturing Plant, Food & Beverage Factory, Advertising Company

Video technical support, Spare parts, Field maintenance and repair service

None

None

New

Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware

Cartons, Bags, Case

Plastic, Wood

Semi-Automatic

Electric

AC380V 50HZ 3PH

150kw

Hebei, China

XINGLONG

about 12-15 tons

customized

ISO9001

Field installation, commissioning and training, Engineers available to service machinery overseas

Energy saving

Semi-auto 4 Color Flexo Printing Slotting Die Cutting Machine

350*500mm

1450*2100mm

Optional

6mm

1450*2300

1450*2100mm

Main Technology Parameter:

Machine inside width | 2300mm |

Max paper coverage area | 1450*2100mm |

Effective printing area | 1450*2000mm |

Min paper coverage area | 350*500mm |

Standard Thickness of printing plate | 6mm |

Working speed | about 0-60sheets |

Printing precision | ±0.5mm |

Thickness of cardboard | |

Main power |

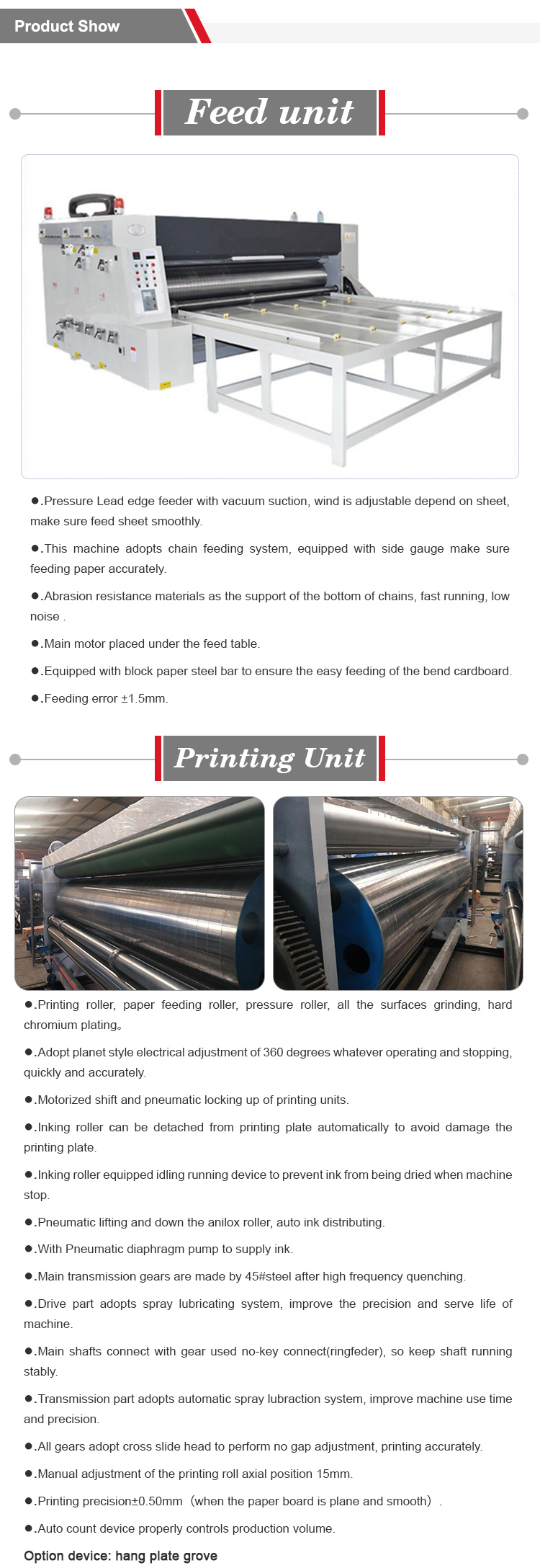

Feeding Unit

n Semi-automatic chain paper feed,and side check plate positioning to ensure accurate paper feed.

n There are four gear chain bars, and each file has three cross-stack cardboard.

n Abrasion resistance materials as the support of the bottom of chains, fast running, low noise and low chain abrasion resistance.

n Main motor placed under the working table.

n Equipped with block paper steel bar to ensure the easy feeding of the bend cardboard.

n Feeding error±1.5mm.

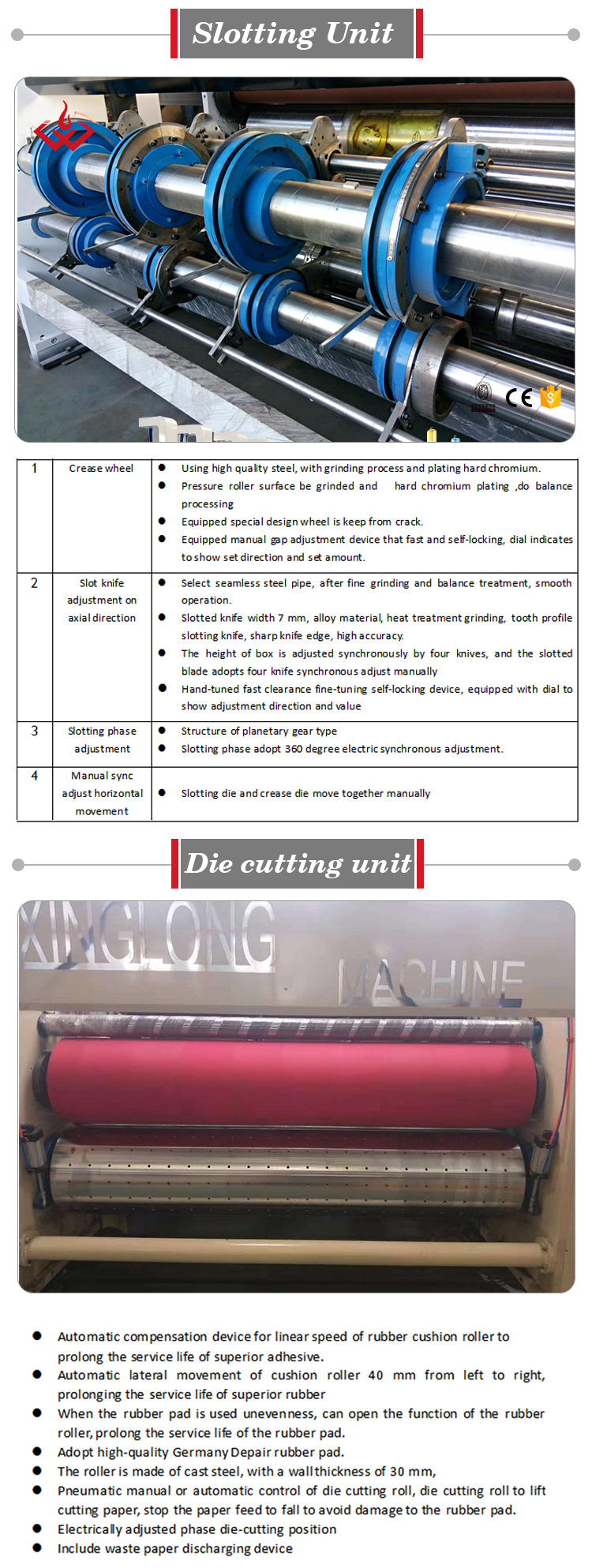

Printing Unit

n Printing roller, paper feeding roller, pressure roller, all the surfaces grinding, hard chromium plating.

n Adopt planet style electrical adjustment of 360 degrees whatever operating and stopping, quickly

and accurately.

n Motorized shift and pneumatic locking up of printing units.

n Inking roller can be detached from printing plate automatically to avoid damage the printing plate.

n Inking roller equipped idling running device to prevent ink from being dried when machine stop.

n Pneumatic lifting and down the anilox roller, auto ink distributing.

n With Pneumatic diaphragm pump to supply ink.

n Main transmission gears are made by 45#steel after high frequency quenching.

n Drive part adopts spray lubricating system, improve the precision and serve life of machine.

n Main gear adopts free-key connection, can long-time keep the printing accuracy.

n Manual adjustment of the printing roll axial position 15mm.

n Anilox and rubber roll drive motor: 0.75 kw

n Phase adjusting motor: 0.37 kw.

n Printing precision±0.50mm(when the paper board is plane and smooth).

n Auto count device properly controls production volume.

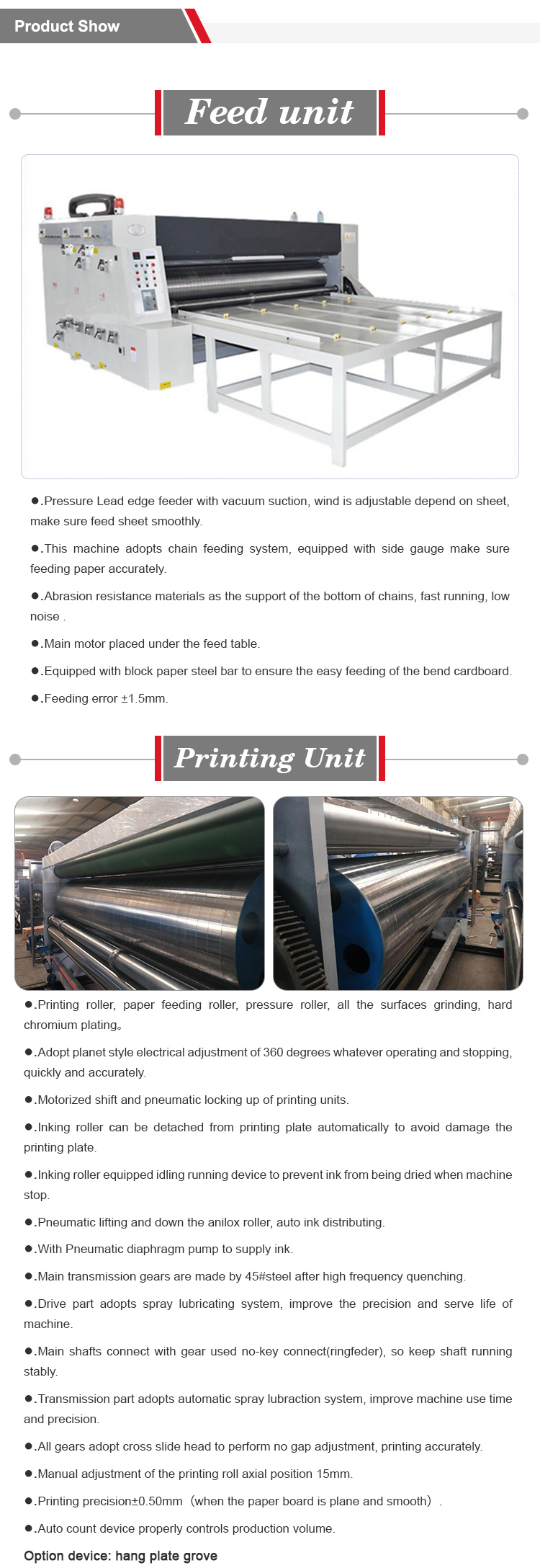

Slotting unit

n The slotting knives pedestal can be worm-type adjustment according to the thickness of card board. ( Three & Five layer only).

n The slitting knives pedestal can be worm-type adjustment according to the thickness of card board. ( Three & Five layer only).

n The back slotting knife (Height of the box) Four knives adjustment synchronous, easy working.

n The main gear adopts free key connection can maintain the long time slotting accuracy.

n Motorized shift and pneumatic locking.

n Electric adjustment Printing phase and slotting position.

n 7mm alloy steel slotting knives with indent heat treatment to enable grinding teeth sharp edge.

n Slotting adjustment motor 0.37kw

n Slotting airframe motor-driven 0.55kw

n Slotting Precision more or less 1.5mm.

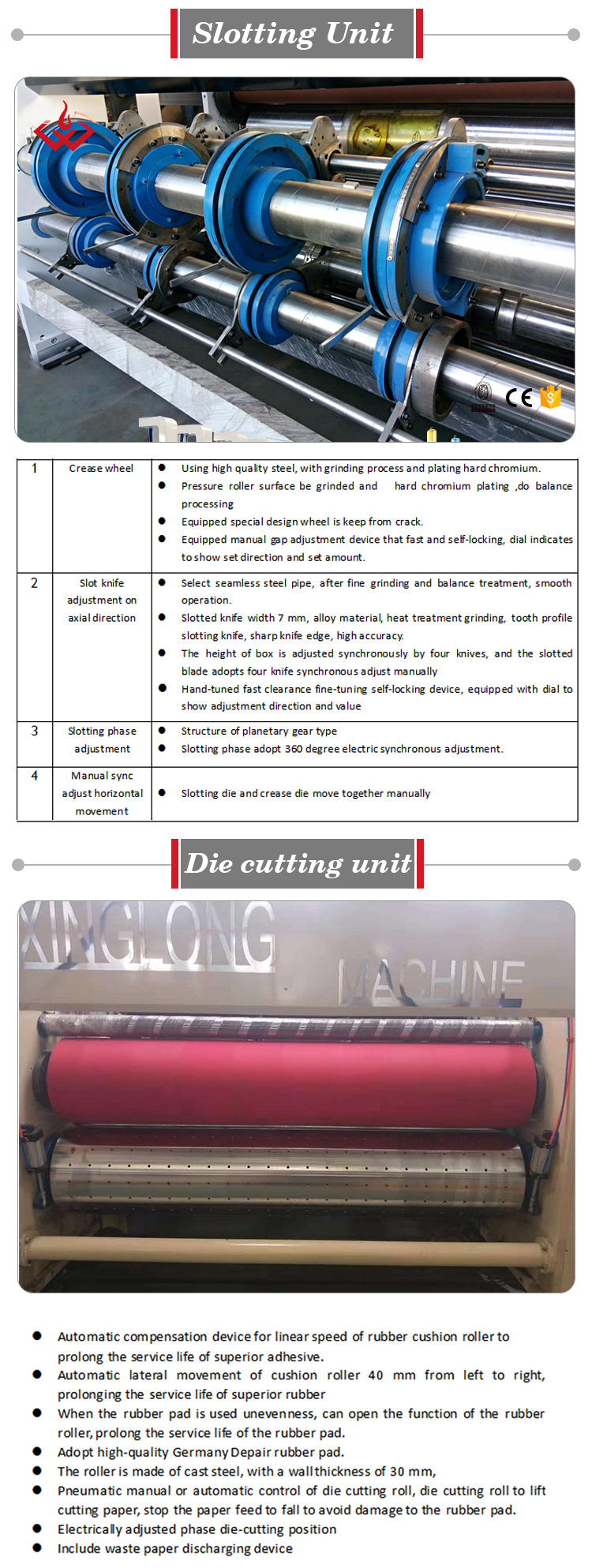

Die cutting

n Glue roller line speed auto repair device, prolong the service life of rubber.

n The rubber roller adopts horizontal automatic position move left and right. The movement distance is 40mm. Prolong the service life of rubber.

n Automatic grinding roller function, prolong the service life of rubber.

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3. Q: How does your factory do regarding quality controlling

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have more than 20 years manufacturing experience of different kinds of box making machines in China. We strictly manufacture and manage according to ISO9001:2000 System and match all the CE standard or stricter standard. Our machine is running well in more than 20 countries. If there have any quality problems, We will help you at any time.

4. Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

If you meet any other questions, please feel free to contact us. click here

Main Technology Parameter:

Machine inside width | 2300mm |

Max paper coverage area | 1450*2100mm |

Effective printing area | 1450*2000mm |

Min paper coverage area | 350*500mm |

Standard Thickness of printing plate | 6mm |

Working speed | about 0-60sheets |

Printing precision | ±0.5mm |

Thickness of cardboard | |

Main power |

Feeding Unit

n Semi-automatic chain paper feed,and side check plate positioning to ensure accurate paper feed.

n There are four gear chain bars, and each file has three cross-stack cardboard.

n Abrasion resistance materials as the support of the bottom of chains, fast running, low noise and low chain abrasion resistance.

n Main motor placed under the working table.

n Equipped with block paper steel bar to ensure the easy feeding of the bend cardboard.

n Feeding error±1.5mm.

Printing Unit

n Printing roller, paper feeding roller, pressure roller, all the surfaces grinding, hard chromium plating.

n Adopt planet style electrical adjustment of 360 degrees whatever operating and stopping, quickly

and accurately.

n Motorized shift and pneumatic locking up of printing units.

n Inking roller can be detached from printing plate automatically to avoid damage the printing plate.

n Inking roller equipped idling running device to prevent ink from being dried when machine stop.

n Pneumatic lifting and down the anilox roller, auto ink distributing.

n With Pneumatic diaphragm pump to supply ink.

n Main transmission gears are made by 45#steel after high frequency quenching.

n Drive part adopts spray lubricating system, improve the precision and serve life of machine.

n Main gear adopts free-key connection, can long-time keep the printing accuracy.

n Manual adjustment of the printing roll axial position 15mm.

n Anilox and rubber roll drive motor: 0.75 kw

n Phase adjusting motor: 0.37 kw.

n Printing precision±0.50mm(when the paper board is plane and smooth).

n Auto count device properly controls production volume.

Slotting unit

n The slotting knives pedestal can be worm-type adjustment according to the thickness of card board. ( Three & Five layer only).

n The slitting knives pedestal can be worm-type adjustment according to the thickness of card board. ( Three & Five layer only).

n The back slotting knife (Height of the box) Four knives adjustment synchronous, easy working.

n The main gear adopts free key connection can maintain the long time slotting accuracy.

n Motorized shift and pneumatic locking.

n Electric adjustment Printing phase and slotting position.

n 7mm alloy steel slotting knives with indent heat treatment to enable grinding teeth sharp edge.

n Slotting adjustment motor 0.37kw

n Slotting airframe motor-driven 0.55kw

n Slotting Precision more or less 1.5mm.

Die cutting

n Glue roller line speed auto repair device, prolong the service life of rubber.

n The rubber roller adopts horizontal automatic position move left and right. The movement distance is 40mm. Prolong the service life of rubber.

n Automatic grinding roller function, prolong the service life of rubber.

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3. Q: How does your factory do regarding quality controlling

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have more than 20 years manufacturing experience of different kinds of box making machines in China. We strictly manufacture and manage according to ISO9001:2000 System and match all the CE standard or stricter standard. Our machine is running well in more than 20 countries. If there have any quality problems, We will help you at any time.

4. Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

If you meet any other questions, please feel free to contact us. click here

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169