- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

YJH1224

xinglong

8441309000

Flexographic Printer

Manufacturing Plant, packaging

Video technical support, Online support, Spare par

New

1200*2400mm

1200*2200mm

300 pcs /min

250 pcs/min

Electric

China,Hebei

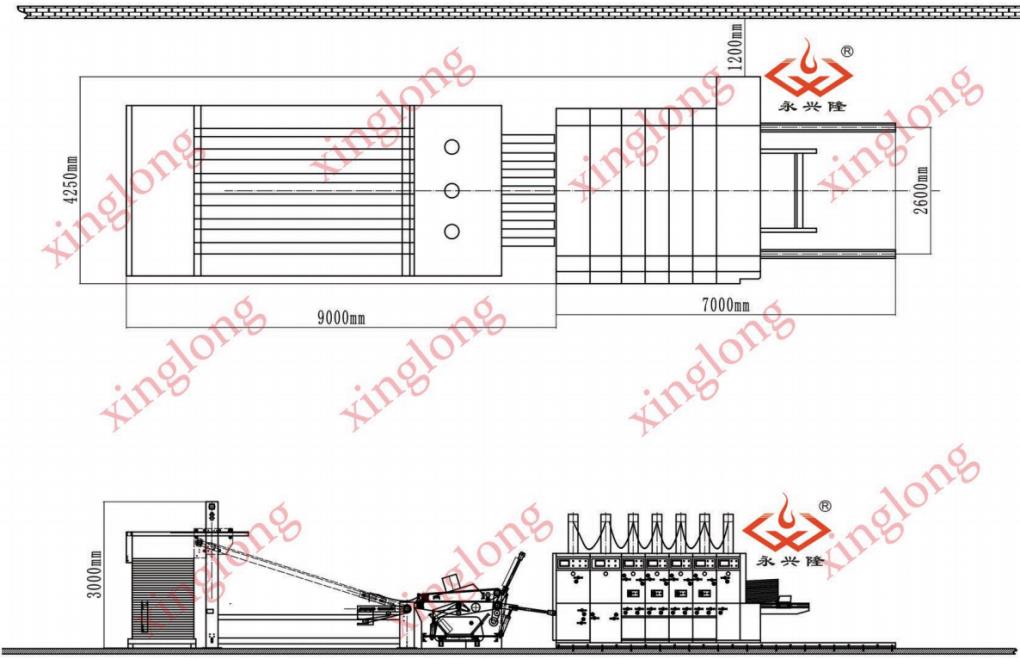

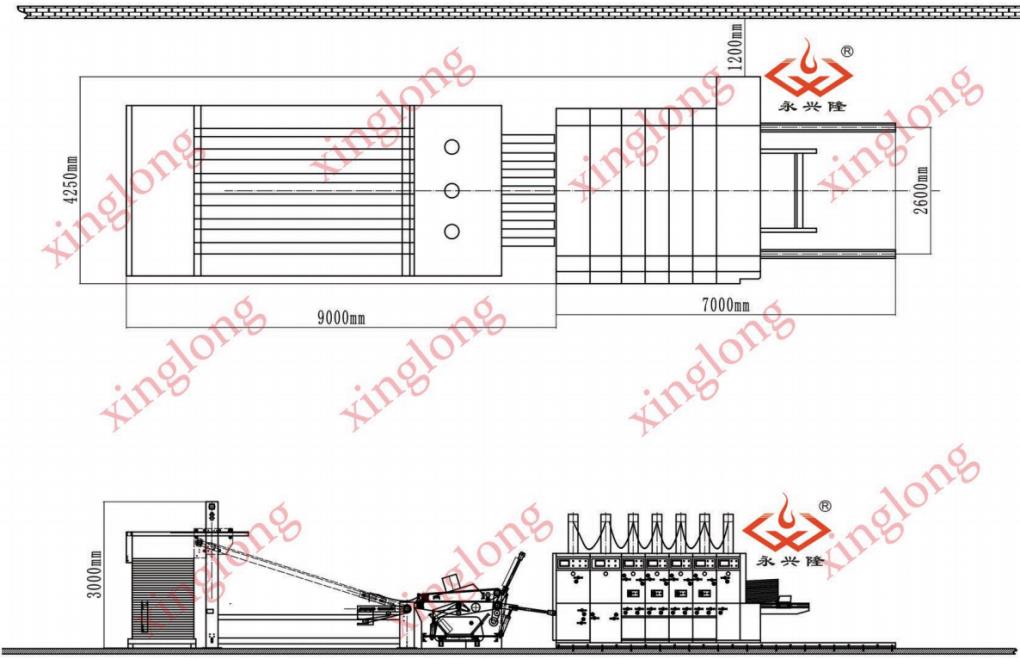

High Speed Full Automatic Flexo Printer Slotter Die Cutter Carton Printing Slotting Die Cutting Machine Corrugated Box Making Machine

The machine can finish multi processes one time such as: printing, slotting, creasing, trimming, corner cutting, punching, die cutting, stacking and so on.

Machine is designed according to high request and reliable function, humanization operation, it can setting, revision, implement, changing and memories in short time, and display data accurately .

Control system: Using industrial man-machine interface and inverter as the core of the electrical control system;Realize the rapid change of production orders, intelligent and comprehensive program control function, make the machine production and adjustment more humane, higher safety, product yield greatly improved.

The main machine wall panel material is HT250, artificial aging treatment, large processing center processing, to ensure high strength and high precision.

All of drive rollers are made of high quality steel with temper and quenching treatment, not change shape when high speed running, hard chrome plated the surface with grinded.

Main drive gears adopt high quality steel with heat treatment with grinded, adopt cross slip system connect each gear, keep gear fix position, ensure transmission precision.

The main drive roller adopt keyless connect, decrease the connection gap, ensure printing precision.

The machine adopts sealed spray lubrication for gear system, engineer oil automatic balance device; keep the oil level equal in each unit.

Lead edge feeder with vacuum sucntion, easy operate, high precision.

After the paper feeding part, printing part and slotting part are combined with the machine, the electric type returns to the zero position. one key color set, the first cardboard is the finished product, thus reducing the waste of paperboard.

Full solid state power distribution system, intelligent Android printing machine CNC system, fast change order, can identify carton design drawings, one key color set, the first cardboard is the finished product, automatic separate and combine the machine body, voice broadcast, remote control, remote detection, human sensing, the lack of ink alarm, mobile phone lock machine, monitoring, high degree of intelligence.

Model | YJ2400 |

Machine inside width (mm) | 2400 |

Max feeding paper size(mm) | |

Max effective printing size(mm) | 1200*2000 |

Max die cutting size(mm) | 1200*2100 |

Min coverage size(mm) | 350*720mm |

Design speed(pcs/min) | 250pcs/min |

Max Working speed(pcs/min) | 200-220 pcs/min |

Standard Thickness of printing plate | 4-6mm |

Printing precision | ±0.5mm |

Thickness of cardboard | 1.0-10mm |

Wall thickness | 50mm |

Main motor power | About 18kw |

High Speed Full Automatic Flexo Printer Slotter Die Cutter Carton Printing Slotting Die Cutting Machine Corrugated Box Making Machine

The machine can finish multi processes one time such as: printing, slotting, creasing, trimming, corner cutting, punching, die cutting, stacking and so on.

Machine is designed according to high request and reliable function, humanization operation, it can setting, revision, implement, changing and memories in short time, and display data accurately .

Control system: Using industrial man-machine interface and inverter as the core of the electrical control system;Realize the rapid change of production orders, intelligent and comprehensive program control function, make the machine production and adjustment more humane, higher safety, product yield greatly improved.

The main machine wall panel material is HT250, artificial aging treatment, large processing center processing, to ensure high strength and high precision.

All of drive rollers are made of high quality steel with temper and quenching treatment, not change shape when high speed running, hard chrome plated the surface with grinded.

Main drive gears adopt high quality steel with heat treatment with grinded, adopt cross slip system connect each gear, keep gear fix position, ensure transmission precision.

The main drive roller adopt keyless connect, decrease the connection gap, ensure printing precision.

The machine adopts sealed spray lubrication for gear system, engineer oil automatic balance device; keep the oil level equal in each unit.

Lead edge feeder with vacuum sucntion, easy operate, high precision.

After the paper feeding part, printing part and slotting part are combined with the machine, the electric type returns to the zero position. one key color set, the first cardboard is the finished product, thus reducing the waste of paperboard.

Full solid state power distribution system, intelligent Android printing machine CNC system, fast change order, can identify carton design drawings, one key color set, the first cardboard is the finished product, automatic separate and combine the machine body, voice broadcast, remote control, remote detection, human sensing, the lack of ink alarm, mobile phone lock machine, monitoring, high degree of intelligence.

Model | YJ2400 |

Machine inside width (mm) | 2400 |

Max feeding paper size(mm) | |

Max effective printing size(mm) | 1200*2000 |

Max die cutting size(mm) | 1200*2100 |

Min coverage size(mm) | 350*720mm |

Design speed(pcs/min) | 250pcs/min |

Max Working speed(pcs/min) | 200-220 pcs/min |

Standard Thickness of printing plate | 4-6mm |

Printing precision | ±0.5mm |

Thickness of cardboard | 1.0-10mm |

Wall thickness | 50mm |

Main motor power | About 18kw |

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169