- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Other, Folding and gluing machine/Corrugated carton machine

Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

New

Apparel, Beverage, Commodity, Food, Machinery & Hardware, Textiles, Medical, Chemical

Cartons

Plastic, Wood

Semi-Automatic

Electric

380v50hz customized

8kw

Hebei, China

Xinglong

2T

customized

CE certification

Easy to Operate

60pcs/min

customized

one year

wooden cases, wooden pallets

gluing carton

Competitive

ZXJ2600

CARTON

4KW

Engineers available to service machinery overseas

Folding and gluing machine/Corrugated carton machine

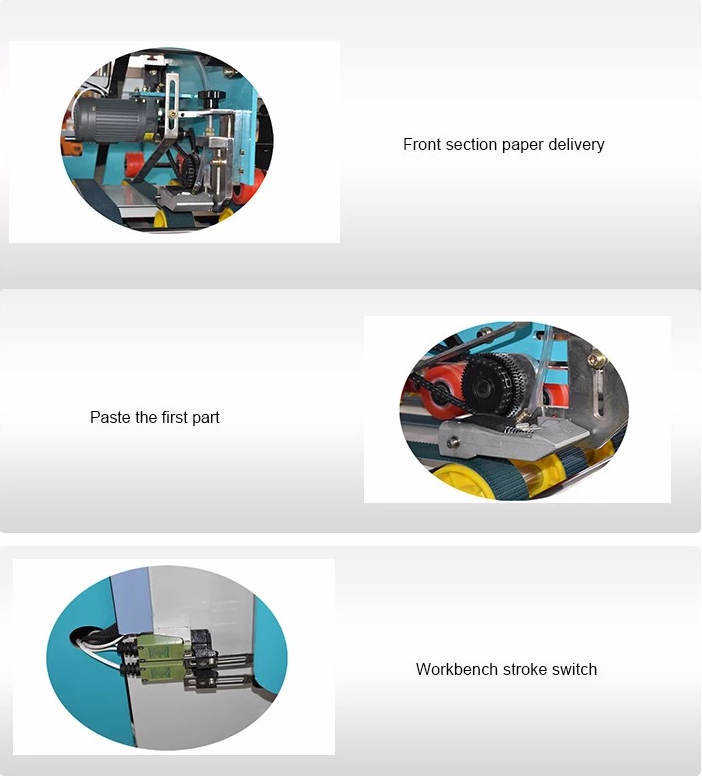

1. Working tableThis machine is the last process equipment of the carton folding, it is used to combination of 3 and 5 layer corrugated cardboard production line( if need to glue 7 layer cardboard, we also can produce according customers’ appointed). Efficiency and production is attractive. The prominent advantage is low cost , strong adhesion, simple operating, saving labor and electric, runs smoothly, it is idea equipment for exporting advanced carton..

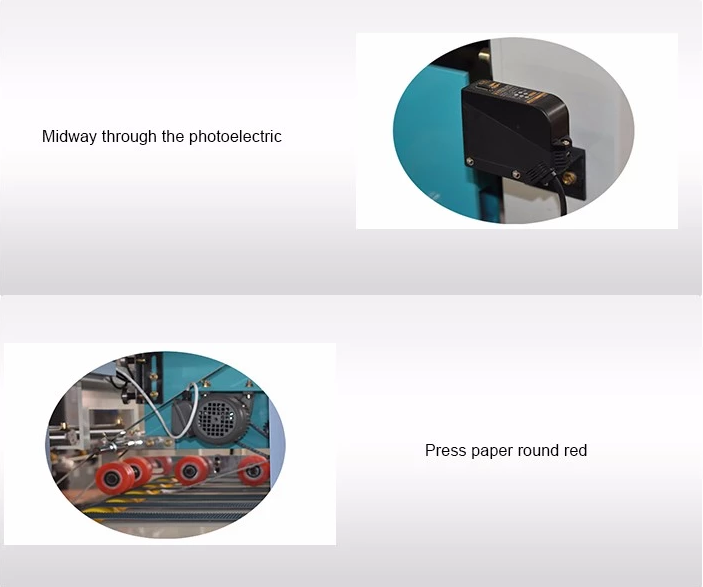

Photoelectric control the feeding, reduce labor and improve work efficiency.

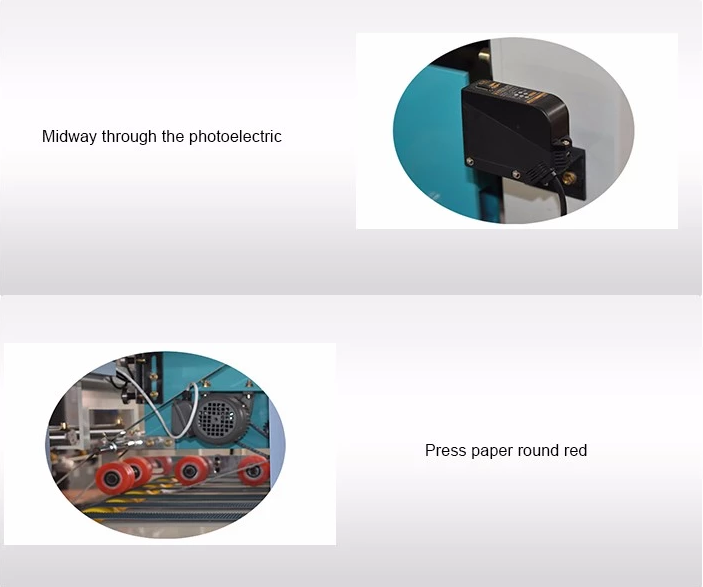

2. Press correction

After gluing and the second pressing to the bonder is smooth and firm.

Equipped automatic correction device to make the carton size is correctly, and effectively avoid knife and fork phenomenon

Fan airing function

Counting output devices and with the photoelectric correlated mechanism, When reaching to the const carton, it outputs automatically.

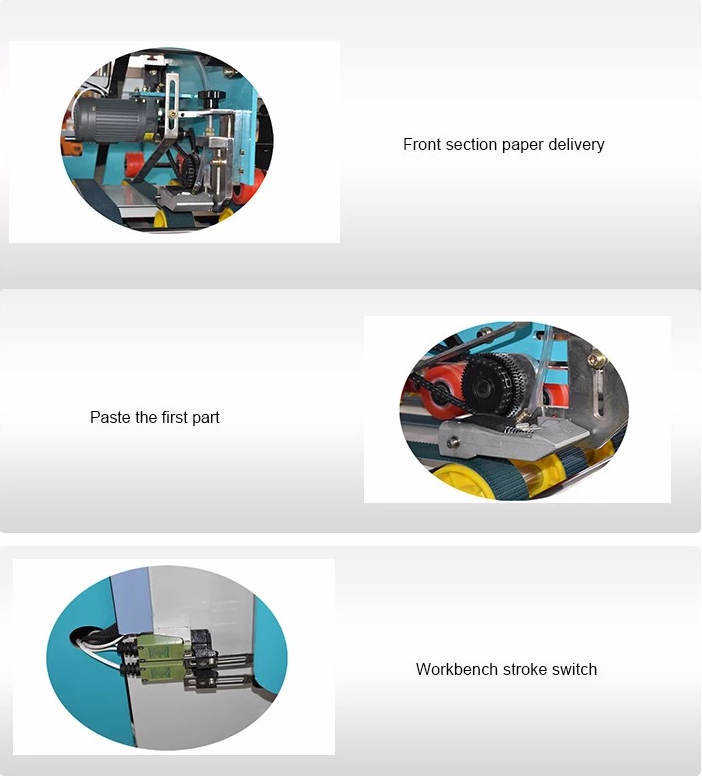

3. Horizontal Output

Press counting output signal, then work automatically, stacking and strapping conviently.

4.Main spare parts

Gear reducer is known brand from China

Electricity components from “Chint”

Conveyor belt is made in XINBEX

PLC from Delta.

The whold gluing head usd of imported material with finish process, wear-resisting, correction resisting, easy to clean.

Max size( length+ width) | 2460 |

Min size( length+ width) | 340 |

Max size(width+ height) | 1515 |

Min size( width+ height) | 240 |

Height of feeding paper | 900 |

Motor power | 4 |

The length of Machine | 4500 |

The Width of Machine | 2100 |

The weight of Machine | 2000 |

Machine speed | 40 |

Dimension(mm) length×width×height | 4000×2000×1900 |

Folding and gluing machine/Corrugated carton machine

1. Working tableThis machine is the last process equipment of the carton folding, it is used to combination of 3 and 5 layer corrugated cardboard production line( if need to glue 7 layer cardboard, we also can produce according customers’ appointed). Efficiency and production is attractive. The prominent advantage is low cost , strong adhesion, simple operating, saving labor and electric, runs smoothly, it is idea equipment for exporting advanced carton..

Photoelectric control the feeding, reduce labor and improve work efficiency.

2. Press correction

After gluing and the second pressing to the bonder is smooth and firm.

Equipped automatic correction device to make the carton size is correctly, and effectively avoid knife and fork phenomenon

Fan airing function

Counting output devices and with the photoelectric correlated mechanism, When reaching to the const carton, it outputs automatically.

3. Horizontal Output

Press counting output signal, then work automatically, stacking and strapping conviently.

4.Main spare parts

Gear reducer is known brand from China

Electricity components from “Chint”

Conveyor belt is made in XINBEX

PLC from Delta.

The whold gluing head usd of imported material with finish process, wear-resisting, correction resisting, easy to clean.

Max size( length+ width) | 2460 |

Min size( length+ width) | 340 |

Max size(width+ height) | 1515 |

Min size( width+ height) | 240 |

Height of feeding paper | 900 |

Motor power | 4 |

The length of Machine | 4500 |

The Width of Machine | 2100 |

The weight of Machine | 2000 |

Machine speed | 40 |

Dimension(mm) length×width×height | 4000×2000×1900 |

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169