- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Other

1.5 years

Field installation, commissioning and training, Engineers available to service machinery overseas

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Construction works , Food & Beverage Shops

Video technical support, Online support, Spare parts, Field maintenance and repair service

None

None

New

water base ink

Hebei, China

XINGLONG

cardboard printing

Automatic

1-4 as sutomers

380V 220V 440V

50kw

15000*4000*3000

15-20tons

CE

Easy to Operate

1-4

flexo water base ink

steel or ceramic

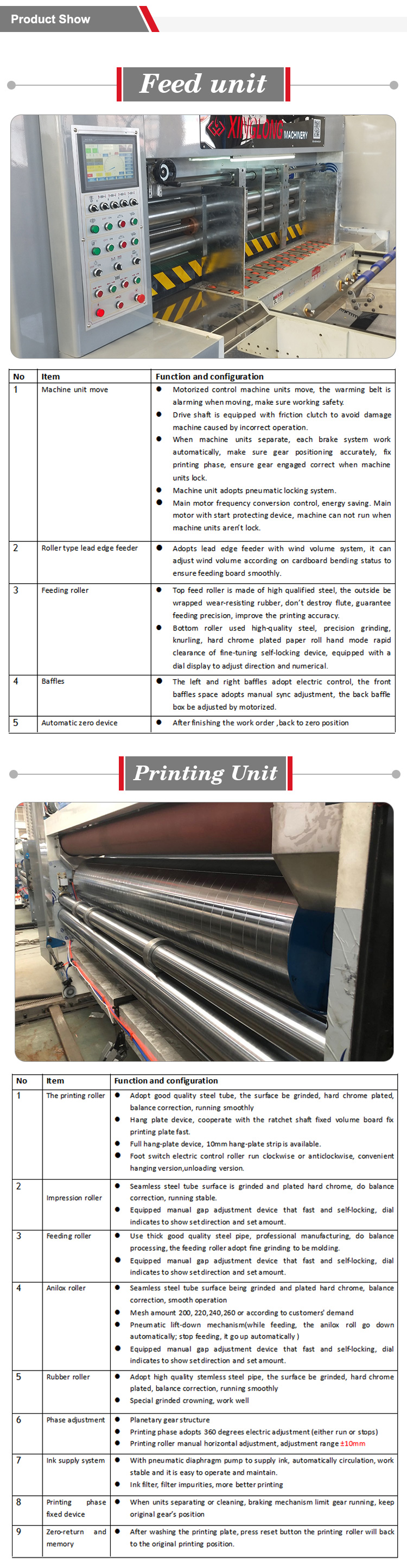

100-150pcs/min

40-50mm

corrugated cardboard

1 Set

1-6

Automatic 4 colors cardboard printing, carton box printing machine, die cutting slotting printing machine

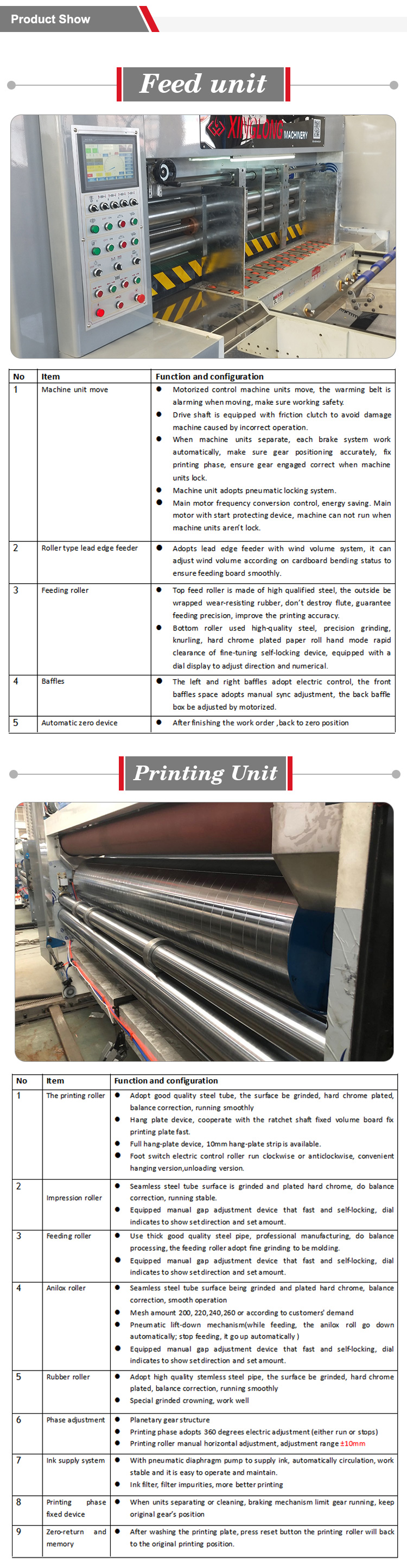

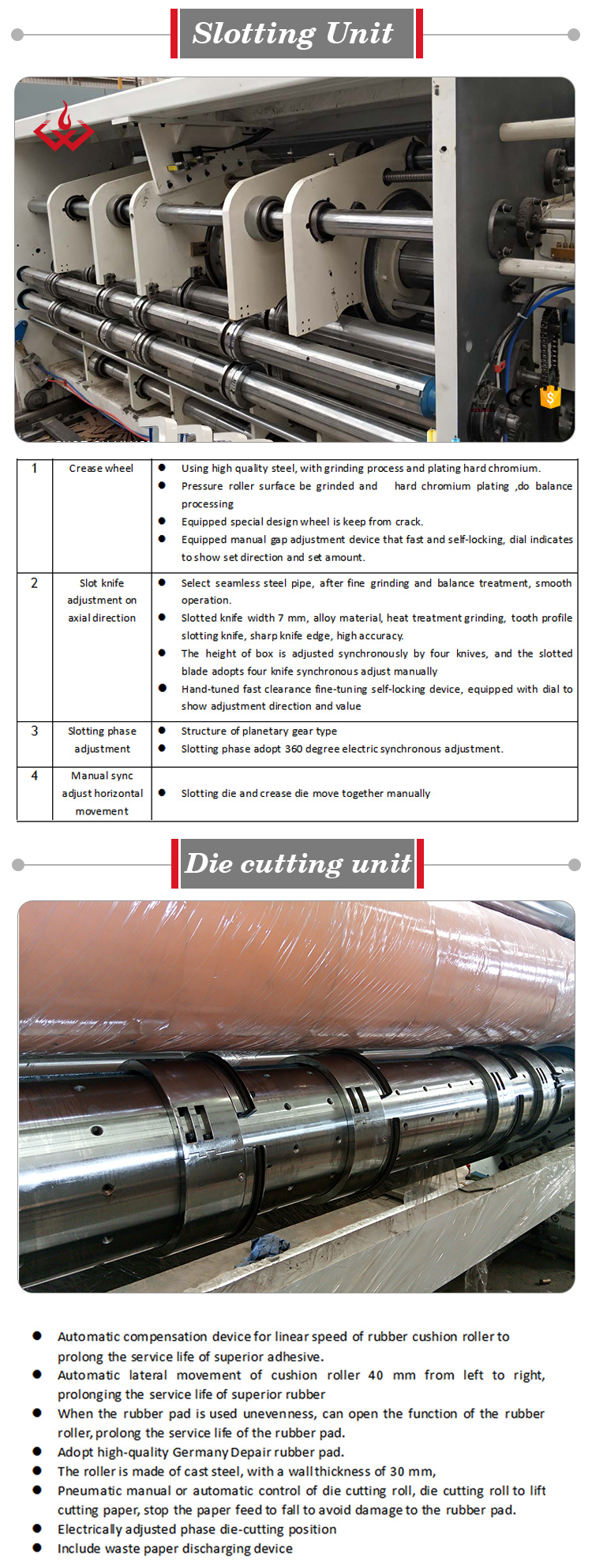

Function and characteristics:

1. The electric appliance of a whole machine adopt the product of SCHNEIDER made in FRANCE.

2. Adopting helical gear driving, the gears are made from high frequency quenching and polishing-gear.

3. All the axles of roller must be chrome-plating in order to increase the hardness.

4. The gears adopt shower type circular lubricating.

5. This machine adopts PLC touching screen control, adopts frequency Converter,rightly and truly.

6. Automatically changes return zero and correct the plate position.

7. Adopting the mould unit designing, the multi-color printing unit can be combined

and linked in any way.

8. The side baffle plate of the feeding department and the grooving department are

adjust by electrically

9. Delivers the paper way to be possible to choose the predestined affinity to deliver the paper system.

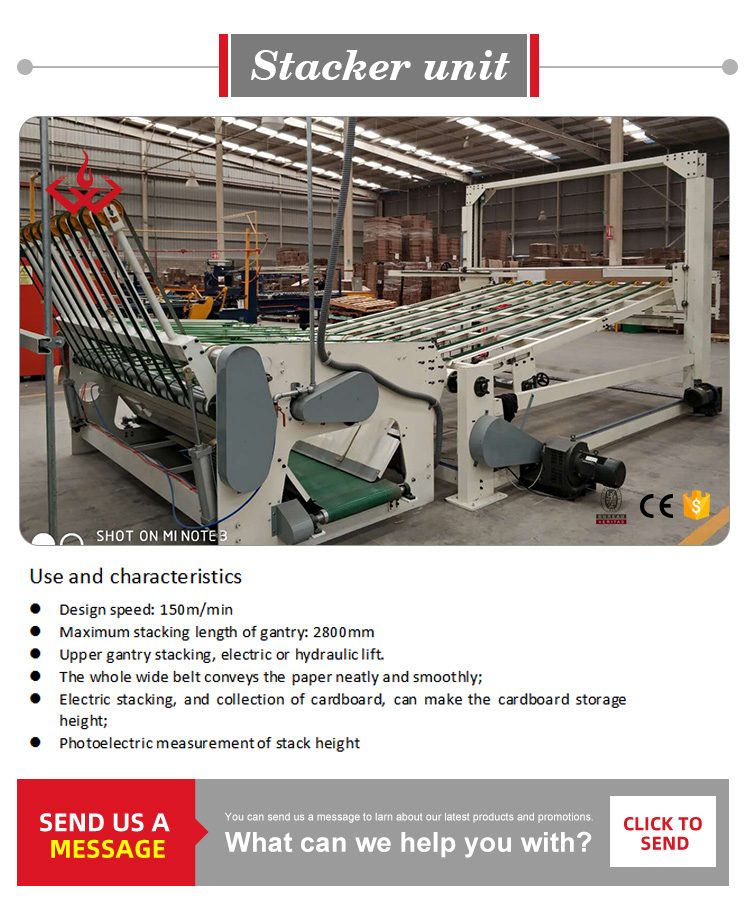

Main technology parameter:

Parameter | Model | ||

1300*2000 | 1300*2200 | 1300*2400 | |

Max.machinery speed (pcs/min) | 120 | ||

Economic printing speed (pcs/min) | 100 | ||

Max. sheet size (mm) | 1300*2200 | 1300*2400 | 1300*2600 |

Min. sheet size (mm) | 380*500 | ||

Min. slotting space (mm) | 160*160*160*160 (Obverse knife) 280*80*280*80 (Reverse knife) | ||

Max. slotting depth (mm) | 320 | ||

Max. sheet thickness (mm) | 12 | ||

Max. printing area (mm²) | 1300*2000 | 1300*2200 | 1300*2400 |

thickness of standard printing plate (mm) | 6 | ||

Automatic 4 colors cardboard printing, carton box printing machine, die cutting slotting printing machine

Function and characteristics:

1. The electric appliance of a whole machine adopt the product of SCHNEIDER made in FRANCE.

2. Adopting helical gear driving, the gears are made from high frequency quenching and polishing-gear.

3. All the axles of roller must be chrome-plating in order to increase the hardness.

4. The gears adopt shower type circular lubricating.

5. This machine adopts PLC touching screen control, adopts frequency Converter,rightly and truly.

6. Automatically changes return zero and correct the plate position.

7. Adopting the mould unit designing, the multi-color printing unit can be combined

and linked in any way.

8. The side baffle plate of the feeding department and the grooving department are

adjust by electrically

9. Delivers the paper way to be possible to choose the predestined affinity to deliver the paper system.

Main technology parameter:

Parameter | Model | ||

1300*2000 | 1300*2200 | 1300*2400 | |

Max.machinery speed (pcs/min) | 120 | ||

Economic printing speed (pcs/min) | 100 | ||

Max. sheet size (mm) | 1300*2200 | 1300*2400 | 1300*2600 |

Min. sheet size (mm) | 380*500 | ||

Min. slotting space (mm) | 160*160*160*160 (Obverse knife) 280*80*280*80 (Reverse knife) | ||

Max. slotting depth (mm) | 320 | ||

Max. sheet thickness (mm) | 12 | ||

Max. printing area (mm²) | 1300*2000 | 1300*2200 | 1300*2400 |

thickness of standard printing plate (mm) | 6 | ||

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169