- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

xinglong

New

1.5 years, 12 Months

Manufacturing Plant, Food & Beverage Factory, Farms, Advertising Company

Video technical support, Online support, Spare parts, Field maintenance and repair service

None

None

Free spare parts, Field maintenance and repair service, Video technical support, Online support

Automatic

Corrugated Carton Box

XINGLONG

Customer's Request

Corrugated Carton Printing Slotting Diecutting

150 PCS/min

Lead Edge

CE

25kw

Dongguang Cangzhou Hebei China

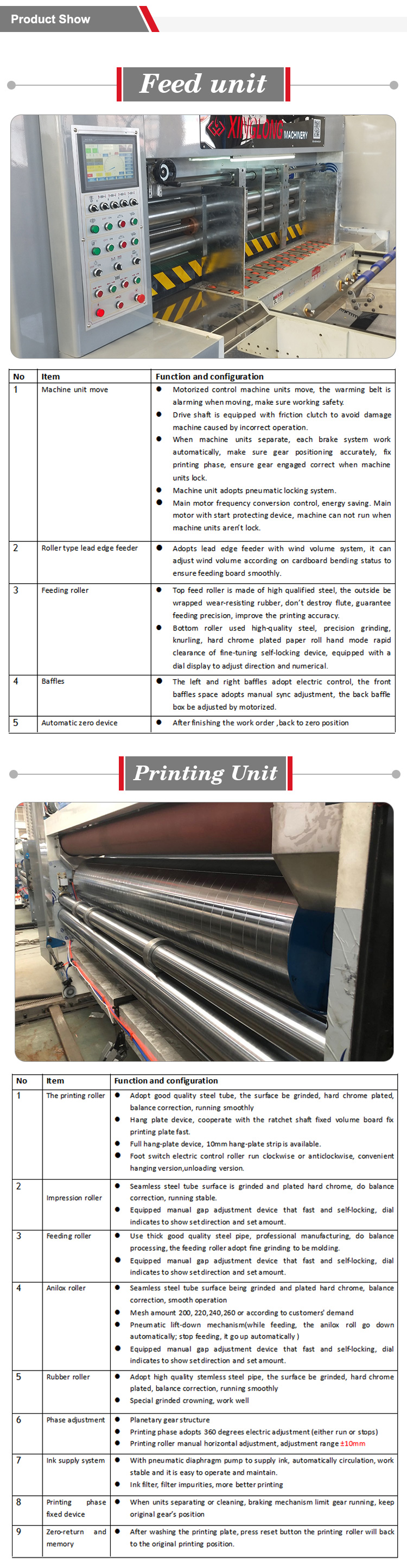

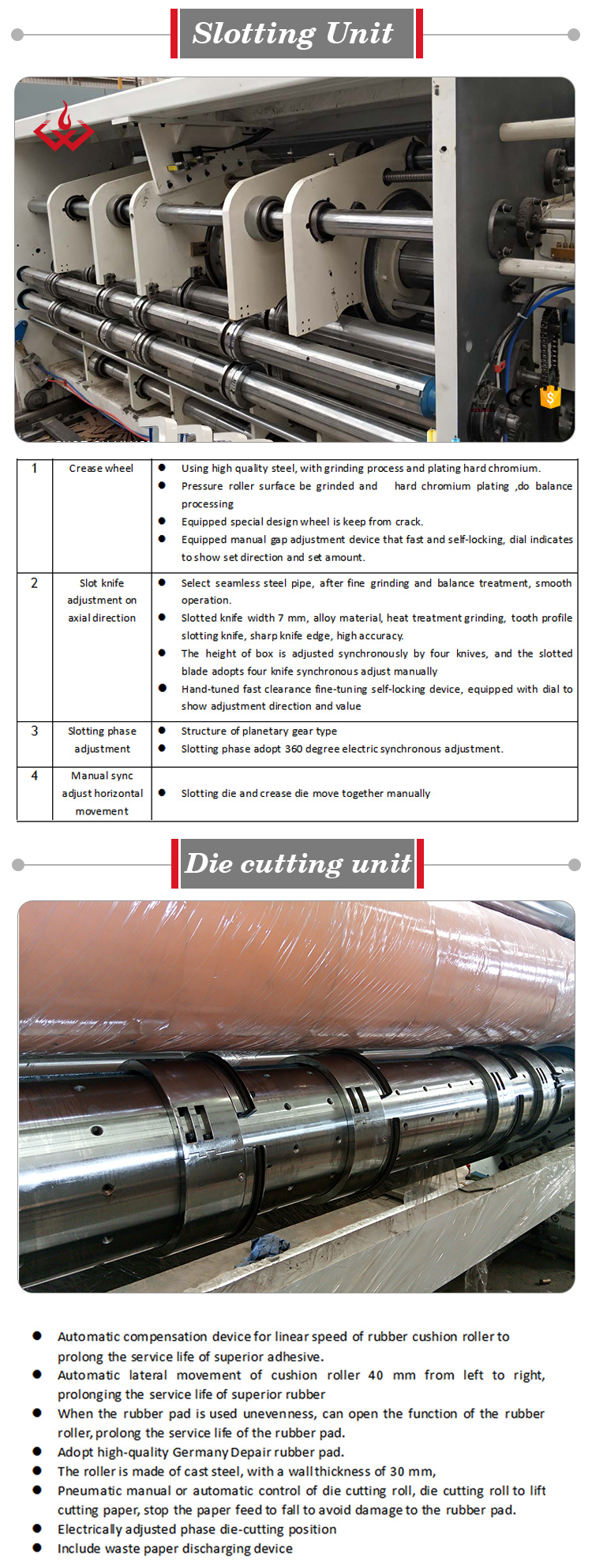

Feeding Unit

1. PLC Control Lead edge feeder, Frequency Converter Motor Quick react

2. Mechanical driving, feeding paper with high precision

3. Working speed and quantity digital display

4. Equipped with dust suck removing device to improve printing quality.

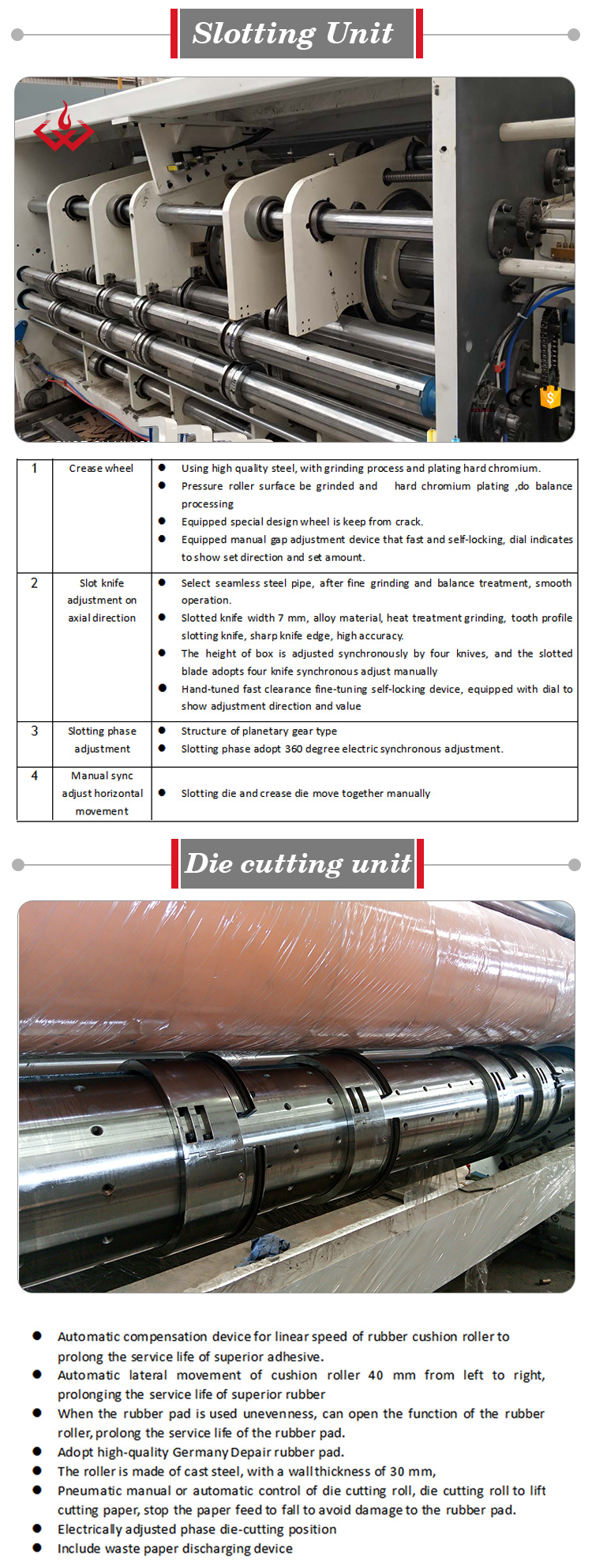

Printing unit

1. Quick change printing plate device.

2. The roller space adjustment adopt self locking structure.

3. The horizontal /phase adjustment of Printing plate adopt PLC and Electric 360 degree adjustment

4. The phase fix device adopt cylinder brake

5. Pneumatic diaphragm pump inking, automatic circle, automatic cleaning

6. Cleaning printing plate memory function

7. Anilox roller adopt pneumatic up/down device synchronous with feeder

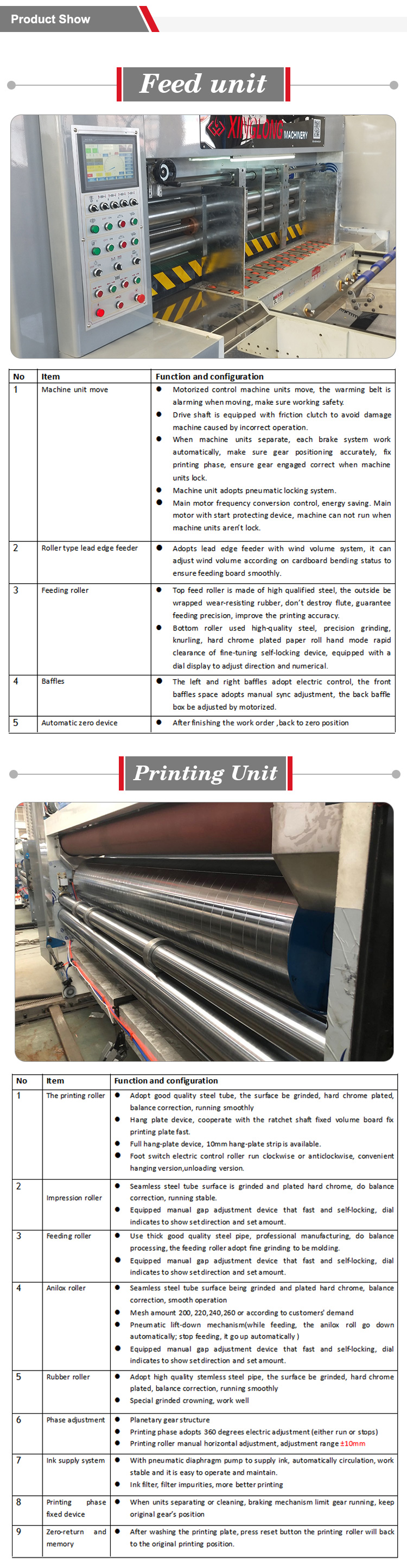

Die cutting unit

1. Rubber roller adopt mechanical spiral lateral movement

2. Die cutting phase adopt PLC and electric 360 degree adjustment

3. Die cutting lateral adjustment adopt PLC and digital adjustment

4. The space of rubber roller and die cutting roller adjustment adopt self locking structure

5. With the unique speed compensation device

8. With rubber repair device

AYM1020 | AYM1224 | AYM1426 | |

Machine speed | 150 sheet/min | 150 sheet/min | 150 sheet/min |

Economic speed | 120 sheet/min | 120 sheet/min | 120 sheet/min |

Max. paper size | 1000×2000mm | 1200×2400mm | 1400 ×2600mm |

Max. printing size | 1000×1800mm | 1200×2200mm | 1400 ×2400mm |

Skip feeding paper | 1100×2000mm | 1300×2400mm | 1500 ×2600mm |

Min. paper size | 260×500mm | 380×500mm | 380*600mm |

Printing plate thickness | 7.2mm | 7.2mm | 7.2mm |

Feeding Unit

1. PLC Control Lead edge feeder, Frequency Converter Motor Quick react

2. Mechanical driving, feeding paper with high precision

3. Working speed and quantity digital display

4. Equipped with dust suck removing device to improve printing quality.

Printing unit

1. Quick change printing plate device.

2. The roller space adjustment adopt self locking structure.

3. The horizontal /phase adjustment of Printing plate adopt PLC and Electric 360 degree adjustment

4. The phase fix device adopt cylinder brake

5. Pneumatic diaphragm pump inking, automatic circle, automatic cleaning

6. Cleaning printing plate memory function

7. Anilox roller adopt pneumatic up/down device synchronous with feeder

Die cutting unit

1. Rubber roller adopt mechanical spiral lateral movement

2. Die cutting phase adopt PLC and electric 360 degree adjustment

3. Die cutting lateral adjustment adopt PLC and digital adjustment

4. The space of rubber roller and die cutting roller adjustment adopt self locking structure

5. With the unique speed compensation device

8. With rubber repair device

AYM1020 | AYM1224 | AYM1426 | |

Machine speed | 150 sheet/min | 150 sheet/min | 150 sheet/min |

Economic speed | 120 sheet/min | 120 sheet/min | 120 sheet/min |

Max. paper size | 1000×2000mm | 1200×2400mm | 1400 ×2600mm |

Max. printing size | 1000×1800mm | 1200×2200mm | 1400 ×2400mm |

Skip feeding paper | 1100×2000mm | 1300×2400mm | 1500 ×2600mm |

Min. paper size | 260×500mm | 380×500mm | 380*600mm |

Printing plate thickness | 7.2mm | 7.2mm | 7.2mm |

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169