- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Packaging Line, Corrugated carton box making machine

Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Food & Beverage Shops

Video technical support, Online support, Spare parts, Field maintenance and repair service

None

None

New

Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles

Cartons, Film

Paper

Automatic

Steam heating

380v/410v/440v 50Hz

Hebei, China

XINGLONG

about 65mX 5mX 4.5m

about 100tons

CE

1 YEAR

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

Long Service Life

New Product 2020

Provided

Provided

1 YEAR

Gear, Engine, Gearbox

1600mm C flute paper box corrugated roller cardboard production line

A,B,C,E,UV

1200-2200mm

60-120 meters/min

Customized

380V, 50Hz

about130KW(380V 50HZ)

±1mm(manual)

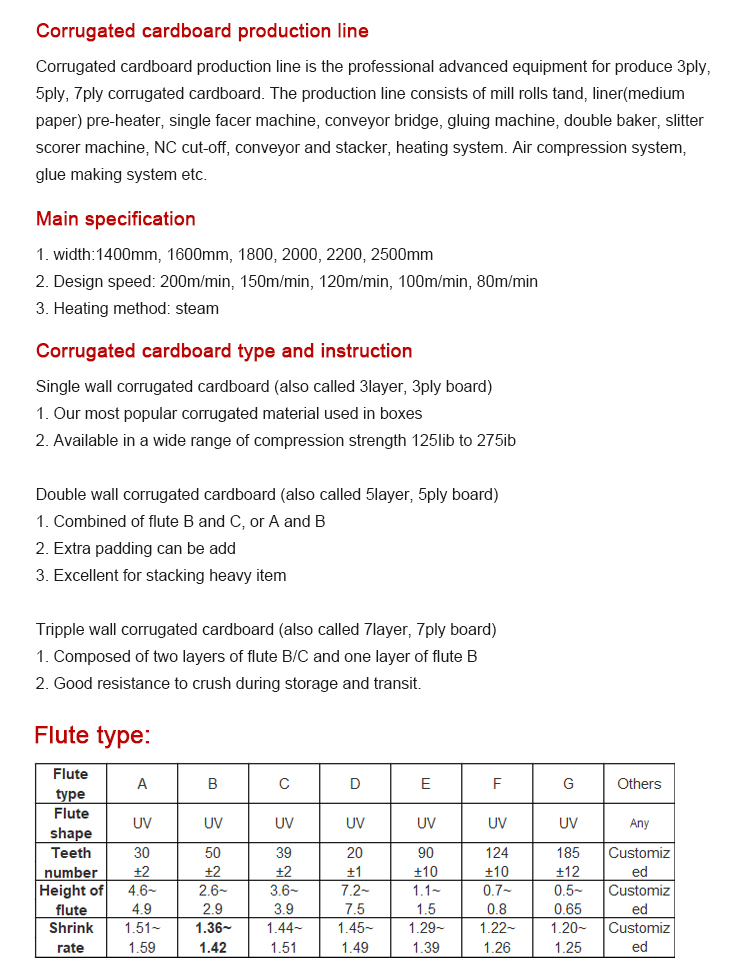

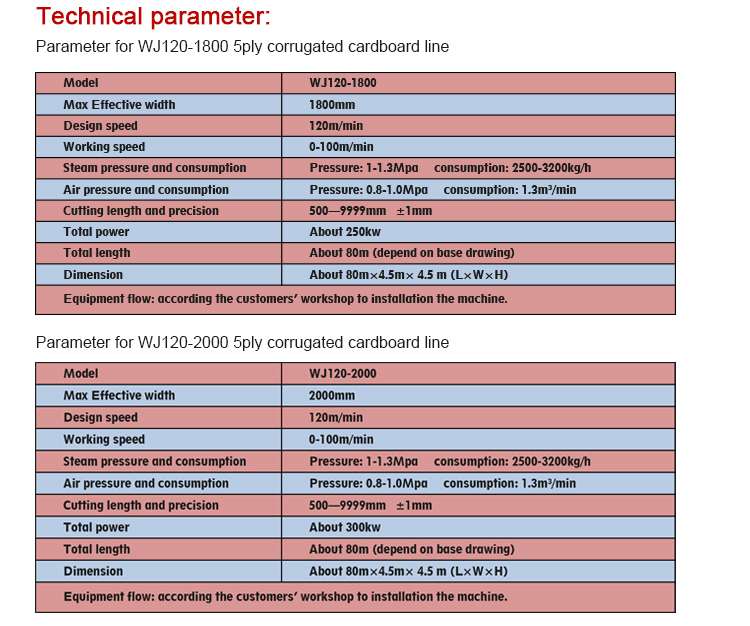

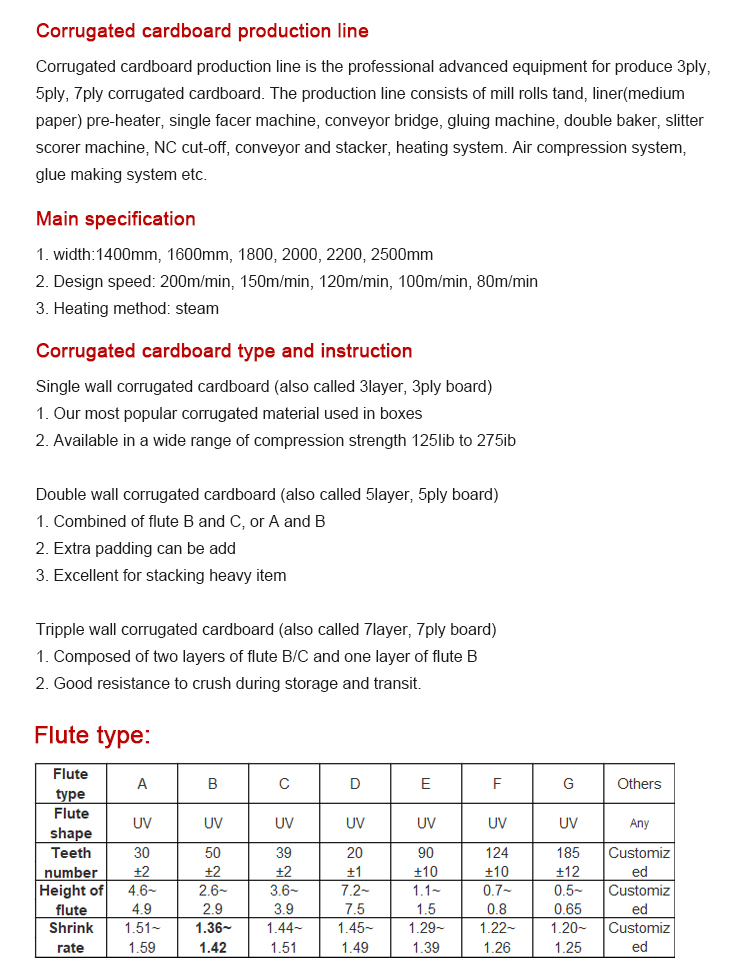

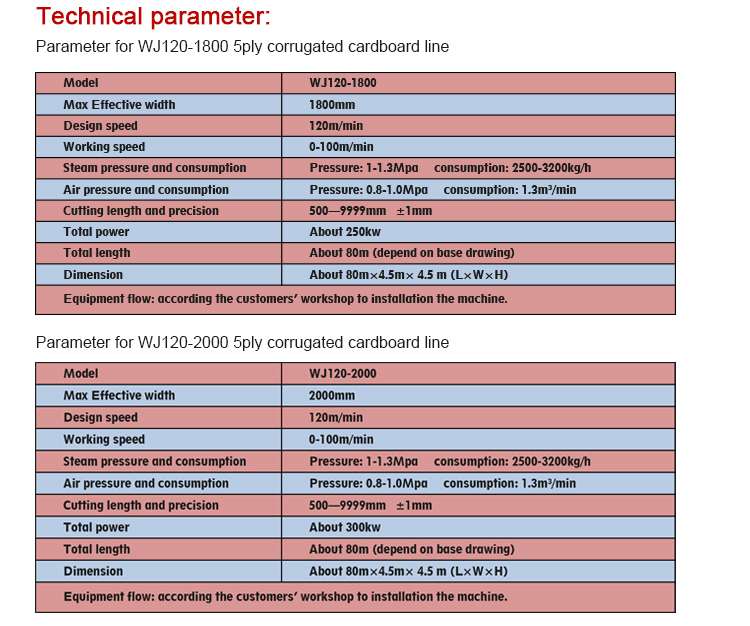

Corrugated cardboard production line is the professional equipment for producing corrugated cardboard. The production line consists of the mill roll stand, liner preheater, single facer machine, conveyor bridge, gluing machine, double facer machine, slitter scorer, cut-off, conveyer and stacker, heating system, air cmpression system and gue making system and so on. We produced different grade 3,5,7 ply corrugated production line with different fitting. On the base of understanding the requirements of the customers and the advanced skills at home and abroad,our company has developed and designed these production lines with the speed 60-220m/min, the paper width 1600-2200mm and A,B,C,E,UV flute production line can satisfy different customrs.

corrugated cardboard making machine main units:

No. | Name | Sets | Comment |

1 | Mill roll stand | 5 | Electric mill roll stand , expansion dop top, pneumatioc brake |

| 2 | Trolley | 10 | Include slide way |

| 3 | Pre-heater | 4 | Φ800, electric adjust heating area |

4 | Single facer | 2 | Vac-sorb,φ320 alloy roller ,cardan drive |

5 | Conveyor bridge | 1 | Electric collection, adsorption tension |

6 | Triply pre-heater | 1 | φ 800, electric adjust heating area |

7 | Gluing machine | 1 | Frequency Synchronous transmission |

8 | Dring part | 1 | 520mm*15pcs heat plate, with up down tension pressure roller (with quality certificate) |

9 | Cooling part | 1 | With up down tension pressure roller, length is 4meters |

10 | Main drive | 1 | Adjustable speed motor |

11 | Conveyor belt | 2 | Quality cotton woven belt, electric lift |

12 | NC cut-off | 1 | Computer control, Straight knive |

13 | Slitter scorer | 1 | 5blades8scores, electric collection, alloy blade |

14 | Make paste system | 1 | With horizontal output |

15 | Glue making system | 1 | Automatic recycle send glue |

16 | Electric control system | 1 | 2control desk of single facer , 1 of main drive, 1of NC cut-off |

17 | Air compressor | 1 | Electric charging |

18 | Steam heating system | 1 | Without boiler and main pipe |

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3. Q: How does your factory do regarding quality controlling?

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

4. Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

Corrugated cardboard production line is the professional equipment for producing corrugated cardboard. The production line consists of the mill roll stand, liner preheater, single facer machine, conveyor bridge, gluing machine, double facer machine, slitter scorer, cut-off, conveyer and stacker, heating system, air cmpression system and gue making system and so on. We produced different grade 3,5,7 ply corrugated production line with different fitting. On the base of understanding the requirements of the customers and the advanced skills at home and abroad,our company has developed and designed these production lines with the speed 60-220m/min, the paper width 1600-2200mm and A,B,C,E,UV flute production line can satisfy different customrs.

corrugated cardboard making machine main units:

No. | Name | Sets | Comment |

1 | Mill roll stand | 5 | Electric mill roll stand , expansion dop top, pneumatioc brake |

| 2 | Trolley | 10 | Include slide way |

| 3 | Pre-heater | 4 | Φ800, electric adjust heating area |

4 | Single facer | 2 | Vac-sorb,φ320 alloy roller ,cardan drive |

5 | Conveyor bridge | 1 | Electric collection, adsorption tension |

6 | Triply pre-heater | 1 | φ 800, electric adjust heating area |

7 | Gluing machine | 1 | Frequency Synchronous transmission |

8 | Dring part | 1 | 520mm*15pcs heat plate, with up down tension pressure roller (with quality certificate) |

9 | Cooling part | 1 | With up down tension pressure roller, length is 4meters |

10 | Main drive | 1 | Adjustable speed motor |

11 | Conveyor belt | 2 | Quality cotton woven belt, electric lift |

12 | NC cut-off | 1 | Computer control, Straight knive |

13 | Slitter scorer | 1 | 5blades8scores, electric collection, alloy blade |

14 | Make paste system | 1 | With horizontal output |

15 | Glue making system | 1 | Automatic recycle send glue |

16 | Electric control system | 1 | 2control desk of single facer , 1 of main drive, 1of NC cut-off |

17 | Air compressor | 1 | Electric charging |

18 | Steam heating system | 1 | Without boiler and main pipe |

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2. Q: What is your minimum order quantity, can you send me samples?

A: Our minimum quantity is 1 set, as our product is machinery equipment, it’s difficult to send you samples, if you have any questions about the products, please feel free to contact us for more detail, we are glad to provide you more information such as specifications, video, etc.

3. Q: How does your factory do regarding quality controlling?

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

4. Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.

(+86)-0317-7751029 / (+86)-151-3371-5169

ivyli@xlcartonmachine.cn

(+86)-151-3371-5169